Article from LEDinside

Ledman has been proactively researching technologies and processes related to glass substrates and officially launched the world’s first PM Glass Substrate Micro LED display in October last year. At that time, the market did not realize that this exploration could potentially open up a new competitive field. By innovatively applying PM Glass Substrate technology, Ledman is capable of creating high-cost-performance products that excel in energy efficiency, screen temperature control, and significantly lower costs. This innovation is seen as a crucial entry point for pushing large-scale Micro LED displays into the consumer market.

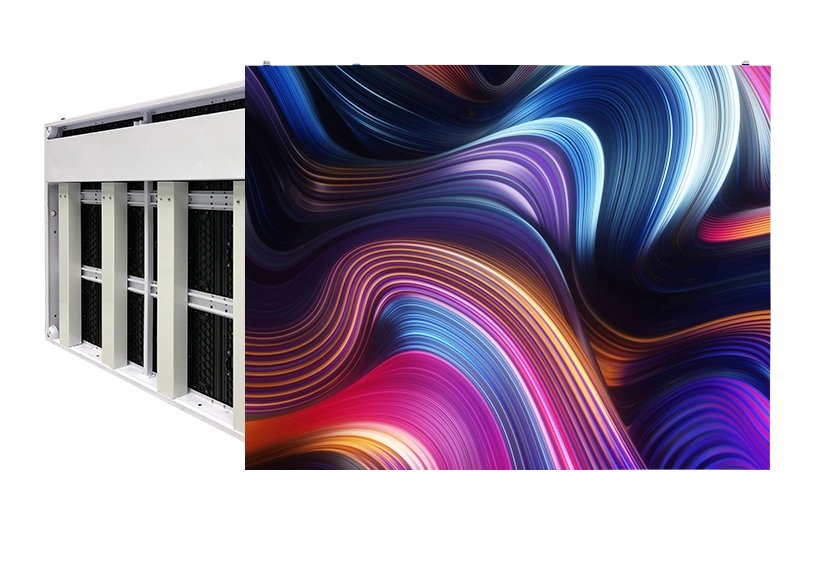

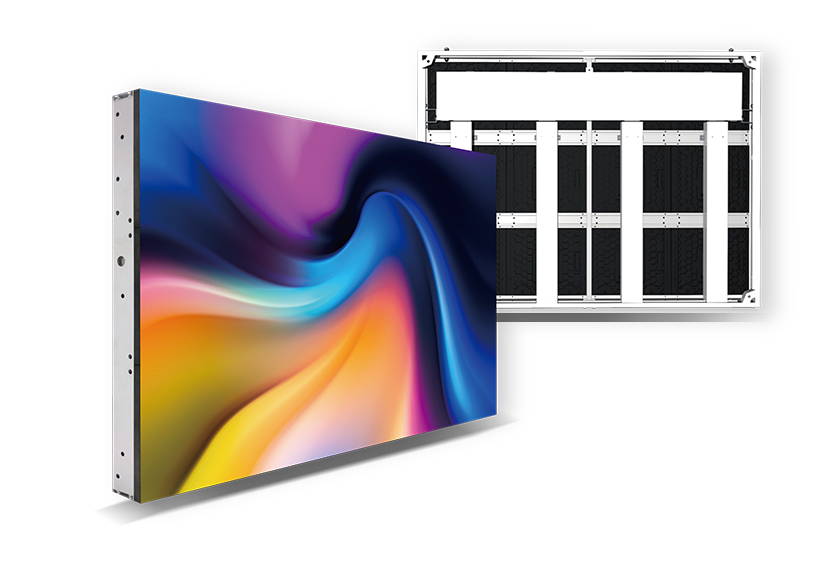

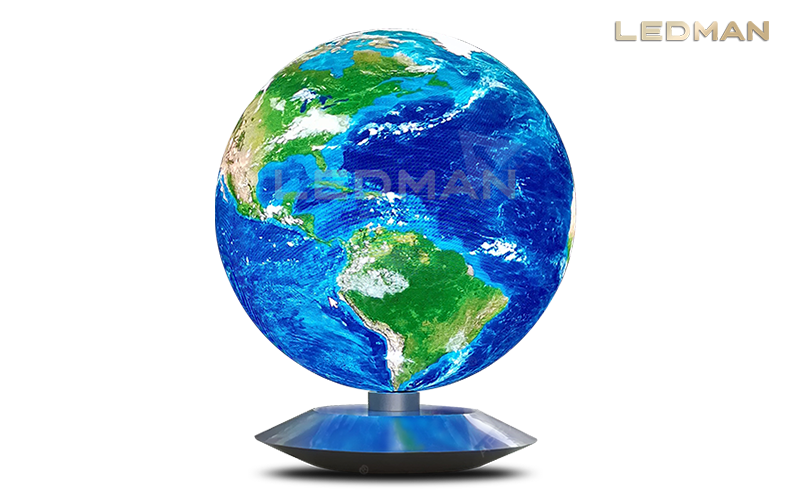

Due to the outstanding cost and performance advantages of PM Glass Substrate display panels, Ledman has begun exploring their application in commercial and consumer fields such as conference rooms, education, and household giant video walls. In the home market, Ledman has initially launched a 220-inch glass-based Micro LED 4K Household Giant Video Wall.

Why Glass Substrates?

The reduction in the size of LED light-emitting chips is an effective path to lower costs for large-scale Micro LED displays. Currently, PCB substrates are nearing the limit of the LED chip sizes they can support, whereas glass substrates can accommodate smaller LED chips, which can significantly reduce the cost of LED displays. Additionally, Ledman’s unique PSE technology allows for achieving nearly the same resolution as existing products with fewer LED chips and fewer driver ICs. This means that Ledman’s next generation of large-scale Micro LED displays will not only use cheaper glass substrates and smaller, more affordable LED chips, but also require significantly fewer microchips. This combination paves a clear path for reducing the cost of Micro LED display products.

However, the miniaturization of Micro LED chips presents several challenges, such as reduced peak efficiency and etching sidewall damage. Techniques like sidewall passivation and DBR (Distributed Bragg Reflector) are key to improving light efficiency. Miniaturization also affects internal quantum efficiency, so strategies to enhance crystal quality, reduce defects, and optimize carrier transport are crucial for improving light efficiency across a wide temperature range.

Committed to PM + Glass Substrate + Micro LED Technology

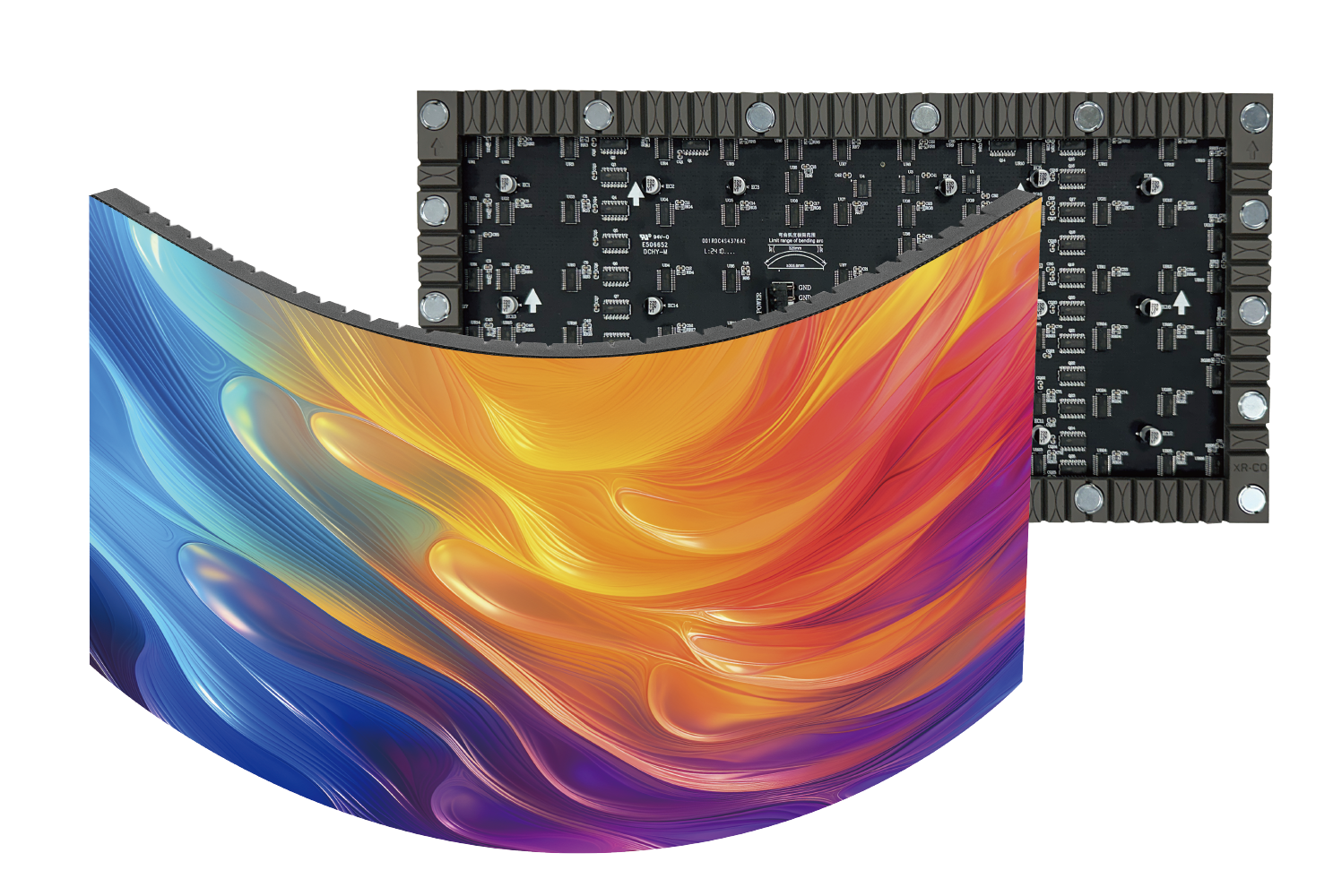

In the market, there are various new solutions for the substrate and driver combinations for Micro LED displays. The AM-driven glass substrate solution offers advantages like independent pixel control, low flicker, and high efficiency with low power consumption, but it also faces challenges in mobility, off-state leakage current, power consumption, and cost. When it comes to large screen splicing, TFT glass substrates still need to overcome issues like sidewall routing and thick copper technology.

On the other hand, the PM-driven glass substrate solution is an innovative route that lights up the Micro LED screen through row-column scanning. While the drive control uses a relatively mature matrix structure, it still faces a series of technical challenges, including massive through-hole drilling, circuit preparation, process selection, stress relief, and substrate flattening.

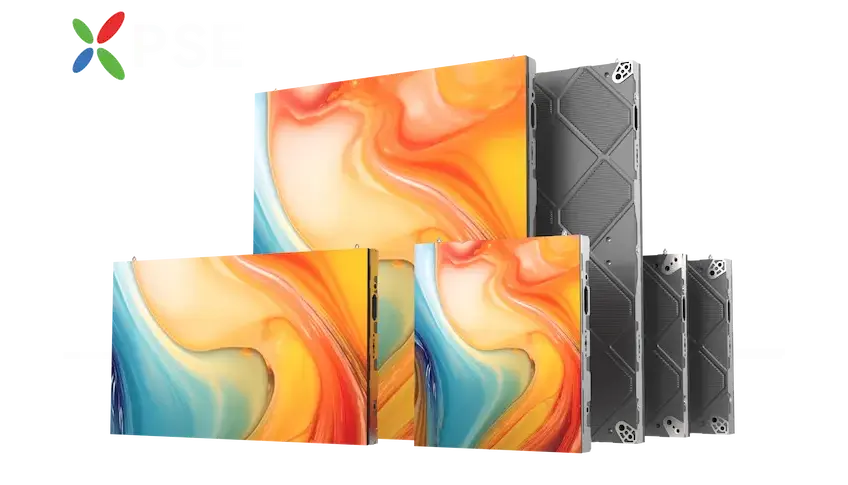

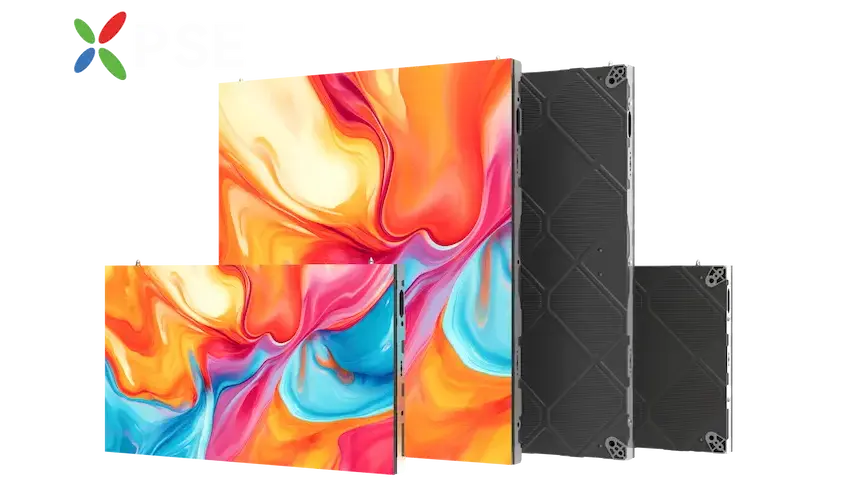

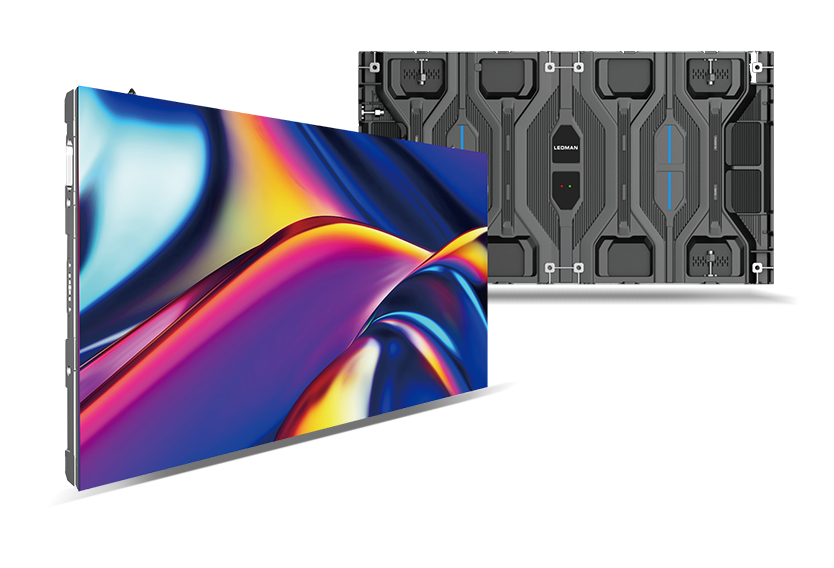

To accelerate the market launch of Micro LED displays, Ledman has launched a project to explore PM-driven structure and glass substrate solutions over five years before, collaboratively overcoming numerous technical and packaging challenges. By leveraging Ledman’s advanced COB packaging process, they have successfully completed several pilot production processes.

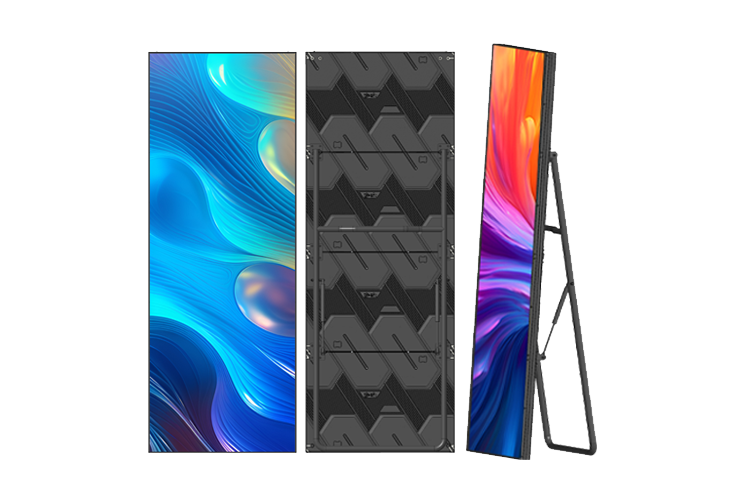

Currently, Ledman has achieved small-scale trial production of PM Glass Substrate Micro LED display panels. This product will be applied in LEDMAN LEDHUB Interactive Conference AlO, LEDMAN LEDHUB Interactive Education AlO, and ultra-high-definition household giant video walls. It will cater to a wide range of large-size Micro LED display products and solutions, fully meeting the low-cost, low-energy consumption needs of various scenarios in future specialized, commercial, and home display fields.