LEDMAN UHD Household Video Wall New Product Launch Successfully Held in Shenzhen

On January 21, LEDMAN’s “Bring the World into Your Living Room” UHD Household Video Wall new product launch was

On January 21, LEDMAN’s “Bring the World into Your Living Room” UHD Household Video Wall new product launch was

Ledman Optoelectronic’s custom-built 275-inch 8K Ultra-HD Micro LED mega screen has successfully arrived at the iconic San Siro Stadium, the

Choosing a new screen in 2026 often leads buyers to the same question: QLED or Mini LED? Both terms

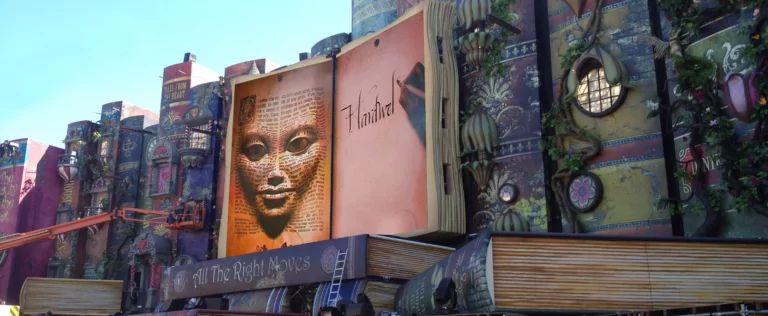

In a landmark project for the Out-of-Home (DOOH) advertising industry in Africa, two mega digital billboards with a combined area

Recently, LEDMAN has successfully lit up and put into operation a customized LED ultra-high-definition display solution for the command center

Choosing the right stage LED screen can shape the entire atmosphere of your event. A clear, vibrant display helps your message

SHENZHEN, November 11, 2025 – The grand product launch event for the “Ledman’s UHD King Icescreen” was successfully held in

Mini LED and Micro LED are everywhere in discussions about the next generation of screens, yet many people still wonder what

Recently, Ledman’s 275-inch 8K Ultra HD Micro LED large screen was shipped out with the first batch of broadcasting equipment for

Please contact us if you have any needs

TOP